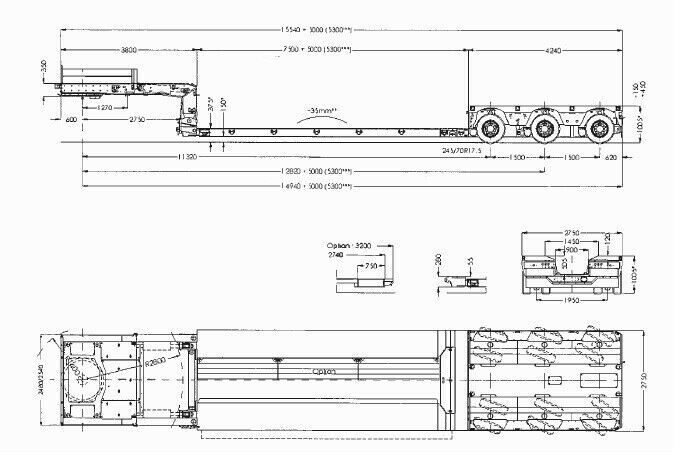

Faymonville 3-Achs-Tiefbett mit Pendelachsen

نشرت: 8شهر 6يوم

نشرت: 8شهر 6يوم

Germany, Martener Hellweg 100, 44379 Dortmund, Germany

Germany, Martener Hellweg 100, 44379 Dortmund, GermanyGooseneck, rigid, in central tube design:

Gooseneck in SNT design to optimize the loading area length, length 3.800 mm

Gooseneck can be raised, lowered and detached hydraulically

For Trucks: 6 x 4, 8 x 4 (or 6 x 4 with 1-axle dolly 235 / 75-17.5)

Low deck:

Low deck designed as an extendable vessel bridge "SUPER LOW", design, length approx. 7.500 mm with mechanical locking

The supply lines are protected in the pull-out brackets and automatically adapt to the length of the low bed

Technical note: The extensibility of the loading area has been extended by approx. 300 mm, this is only used to transport "SELF-SUPPORTING LOAD" (container)

Rear chassis:

Rear chassis with closed outer frame

Covered with checker plate

Continuous prism excavator trough (approx. 1.450 x 900 x 505 mm), open at the rear

"PENDEL-AXLE", all axles hydromechanically steered

Hose rupture valve on the axle compensation cylinder with automatic RESET function

Hydraulic cylinder with stopcocks and linchpin for securing in the raised position

Technical axle load: 12.000 kg

Hydraulic axle compensation

Axis tool

Braking system:

WABCO EBS brake system in accordance with EU regulations

Tyres:

245/ 70 R 17.5

Painting:

6-component finishing:

Complete steel construction shot-peened after welding

One layer of zinc-based base paint, one layer of adhesive primer

Final painting of axes 2 layers of 2-component paint (acrylic) painted in one color in gray, then sealing of the cavities with special wax

Rims in silver

Trailer: RAL 5010 gentian blue

Metallization:

Part of HRM metallization (High Resistance Metallization)

The entire steel construction is shot-peened, then the defined visible surfaces are hot-finished with ZINACOR 850 (zinc 85% -alu15%).

Steel construction:

Steel construction made from high-strength fine-grained steels

Steel qualities:

S355J2 + N / S355MC (yield point 355MPa)

S690QL / S700MC (yield point 690MPa)

Certified welder according to DIN-EN 287-1

MAG welding process according to EN ISO 4063

Shielding gas M21 according to EN ISO 14175

Lighting:

24 volt lighting system in "ASPÖCK-NORDIK full LED"

Design in accordance with EU regulations. ASS3

Additional equipment:

Front wall made of steel, pluggable, approx. 400 mm high

1 pair of pluggable aluminum drop sides on the gooseneck, approx. 400 mm high, in an anodized design

a pluggable aluminum back panel on the gooseneck, approx. 400 mm high, anodized

External support from the gooseneck with mounting holes for screwable lashing rings

The first hole approx. 200 mm from the front, then approx. Every 400 mm

2 pairs of screwable lashing rings included (5.000 daN)

Checkered plate covering over the gooseneck

4 drag shoes with bracket

Illumination of the controls on the gooseneck

Air connection on the gooseneck

Gooseneck with 2 plug-in handrails to the loading area in the area of the folding steps for climbing the gooseneck

1 lashing ring on the left and right on the rear bevel of the gooseneck (LC 6.000 daN)

Connection strip for supply lines to the Truck, attached at the height of the outer frame profile

Hydraulic support traverse to support the gooseneck on the truck unit (or dolly)

Gooseneck in the upper rear area closed with a removable cover

Hydraulic connections from the gooseneck to the low bed with multi-coupling

One locking point approx. Every 500 mm on the extension

1 pair of steel ramps with climbing rails to bridge the hooks of the low bed with fastening bolts

Fastening options at the rear between the external beams of the gooseneck for the low bed ramps

1 lashing ring on the left and right on the front cross member (LC 10.000 daN)

Preparation on the external beams for the removable loading floor

Lashing rings with retaining springs every approx. 1.200 – 1.300 mm on the outside of the inner beams of the loading area

Lashing rings with retaining springs every approx. 1.200 – 1.300 mm on the outside of the external beams of the loading area (LC 10.000 daN)

Recesses above the lashing rings on the top strap of the outer beam

7 pairs of threaded blocks between the lashing rings under the top strap on the outer beam for the assembly of screwable RUD rings VLBG-4

2 pairs of RUD rings VLBG-4 M24 (LC 8000 daN)

Foldable extensions, by approx. 230 mm per side

6 pairs of stanchion pockets, outside on the outer beams of the low bed for stanchions approx. 100 x 50 mm

Preparations for screwable container brackets with safety bolts on the external beams

Boreholes are provided on the external supports to accommodate the holder for 1 x 20` or 1 x 40` container

Mechanical bolt-plate coupling from the low bed to the chassis, for changing the loading area or installing extension beams.

With electro-pneumatic-hydraulic couplings

1 hanging lashing ring on the outside left and right on the rear cross member (LC 10.000 daN)

The outer beams of the low bed are provided with a coated layer of sand to prevent them from slipping

Attachment bar at the front of the rear undercarriage to the low bed for loose docking ramps

2 pairs of stanchion pockets embedded in the outer frame of the rear chassis, for stanchions approx. 100 x 50 mm

1 pair of lashing rings (LC 16.000 daN) in the excavator cavity of the end chassis, in the area of the 2nd axle

1 pair of lashing rings (LC 10.000 daN) on the outside of the rear cross connection in front of the end undercarriage

When attaching a container fastening, the lashing ring must be folded up

4 pairs of lashing rings hanging in the outer frame of the rear chassis (LC 10.000 daN)

1 pair of lashing rings lying at the front in the excavator cavity of the rear chassis (LC 16.000 daN)

1 pair of lashing rings lying behind in the excavator cavity of the rear chassis (LC 10.000 daN)

Rear chassis with beveled corners at the rear

Suspension bar for loose aluminum docking ramps on the vehicle's final traverse

Insertion options at the front and rear in the arm recess of the rear chassis including a plate

Mud flaps across the entire width of the final cross member

Bracket for warning light on the vehicle's final traverse

Electro-hydraulic unit approx. 3 kW for operating the hydraulic processes except for the hydraulic cable winch

Round NATO socket on the connection strip at the front

Two 7-pin sockets on the connection strip at the front

1x NATO black 24N connection according to ISO 1185

1x NATO white 24S connection according to ISO 3731

Holder for the warning signs on the left and right, including a 7-pin socket, under the gooseneck and in front of the first axle and on the rear of the chassis

A 7-pin socket on the end traverse

Central lubrication system

Removable loading floor with approx. 30 mm thick hardwood flooring, insertable between the external beams in three elements

Axle load manometer mounted on the left

4 warning signs approx. 423 x 423 mm extendable by approx. 1.000 mm

Bracket for warning light

Yellow reflective tape on the outside along the entire length of the trailer in accordance with EU guidelines

Yellow reflective tape at the back across the entire width of the trailer in accordance with EU guidelines

EU reflector on the final cross member of the vehicle

Radio remote control for steering

An additional 15-pin socket on the connection strip at the front in accordance with ISO 12098